Creation date

What is biogas?

Biogas is a renewable gas mainly composed of methane and CO2, obtained from the anaerobic degradation - without oxygen - of organic waste. CO2 is one of the gaseous components that contribute most to the production of the greenhouse effect and, as a consequence, to the global warming of our planet.

How is biogas obtained?

Biogas is produced in municipal solid waste (MSW) landfills by the decomposition of organic matter. Thus, under anaerobic conditions (without the presence of air) and under the action of certain bacteria, the organic fraction ferments and produces this gas, which is normally released into the atmosphere. Landfill degassing will prevent the emission of these gases into the atmosphere.

What is it used for?

Mainly to obtain electrical and thermal energy. In our facilities, we take advantage of this renewable energy source by converting it into electrical energy.

What type of energy does biogas generate?

The combustion of the biogas is transformed into electrical energy by a generator. This electrical energy is supplied to the grid by means of a High Voltage Transformer Station with a transformation ratio of 400 V at 25,000 kW.

What are the benefits of biogas?

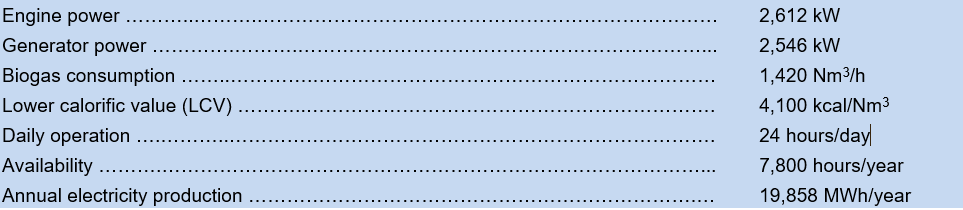

The use and energy recovery of biogas. The energetic use of landfill gas is carried out through the installation of two motor-generator groups with the following characteristics:

Gas consumption is equivalent to 4,495 toe/year and electricity production discharged into the public grid, after deducting the plant’s own consumption, is estimated at 18,720 MWh/year, equivalent to the consumption of 7,500 households in a year.

How does a biogas plant work?

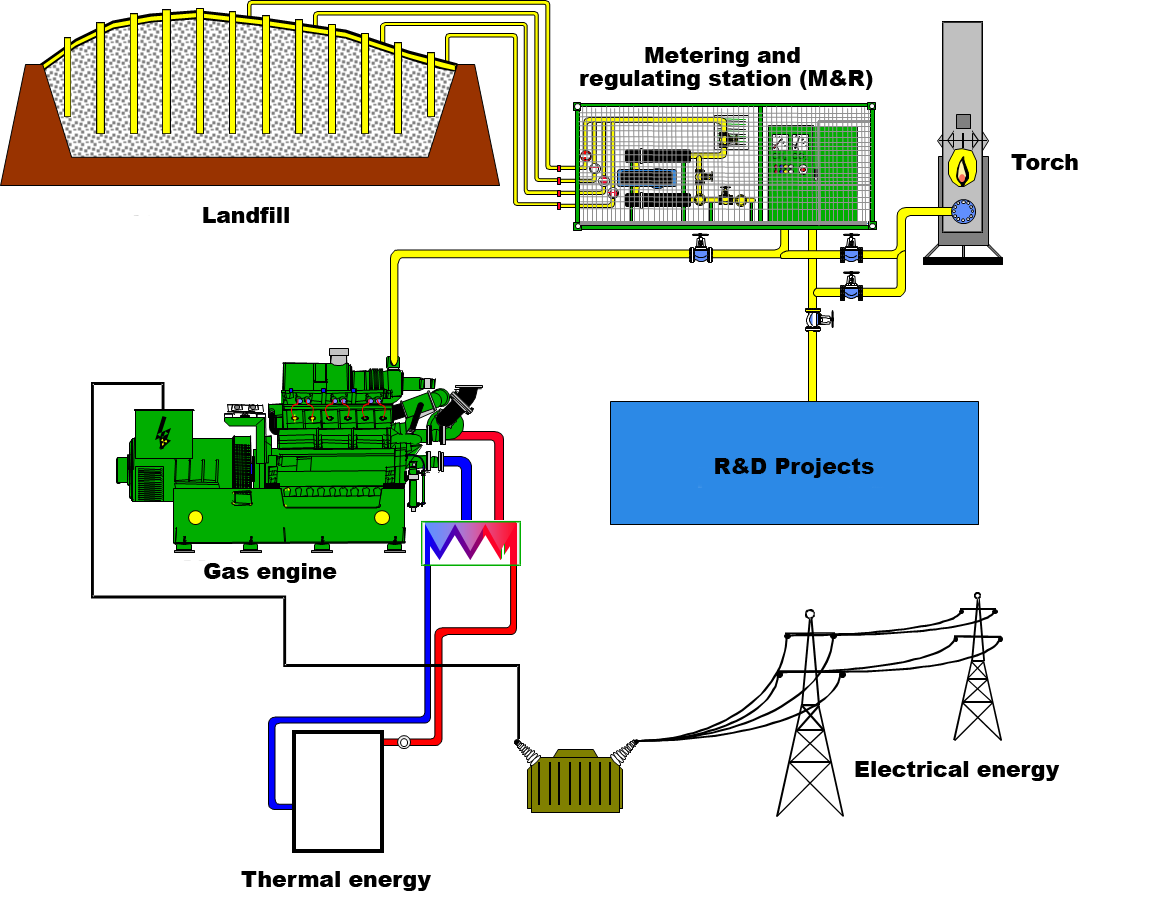

A facility such as the ones Tradebe has at the Montalbán Environmental Complex in Córdoba and at the Valsequillo Environmental Complex in Antequera (Málaga), consists of the following set of equipment and systems:

- Biogas collection and transport system.

- Suction, conditioning, and impulsion system.

- Energy recovery system.

- Medium-voltage and low-voltage electrical installation.

- Process control and monitoring system.

Biogas Collection and Transport System. It is made up of wells drilled in the different discharge areas (sealed) with an average depth of 15 m, spaced some 40 m apart. Each of the wells is connected to its corresponding metering and regulating station (M&R) by HDPE pipes.

At the M&Rs, the biogas flow is regulated by means of manifolds and valves, which enables the gas to flow steadily to the main collector.

Aspiration, conditioning, and impulsion system. The captured gas is aspirated by two blowers and propelled to the engines' feed circuit. It is previously subjected to a conditioning process that prepares it to be injected into the two motor-generators.

Energy Recovery System. The electricity produced by these generators is at a low voltage, so it is taken to the transformation centre to be converted into high voltage. Finally, it is supplied to the electricity grid.

Medium-voltage and low-voltage electrical installation. In order to cover the electrical supply needs, the installations have a Medium Voltage Transformer Station with a capacity of two encapsulated dry-type transformers, with a unitary power of 1,600 kVA, a transformation ratio of 15 to 25 kV/420 V, equipped with thermal protection and a General Low Voltage Distribution Board in charge of providing service to all the auxiliary elements of the plant.

Process control and monitoring system. The process control system will consist of a computer and a PLC. The PLC will communicate with the different control elements (blowers, instrumentation, engine computers, etc.) to provide the appropriate information to the control computer. Through the control computer, the information can be transmitted remotely to provide the necessary elements to determine the severity and importance of possible faults, process parameters, etc.